Foundation Problems

This is an unbiased report from “The Home Owners Manual” that is distributed nation wide by the National Realty Marketing (NRM) to realtors. The manual is to be handed out free to home buyers and sellers.

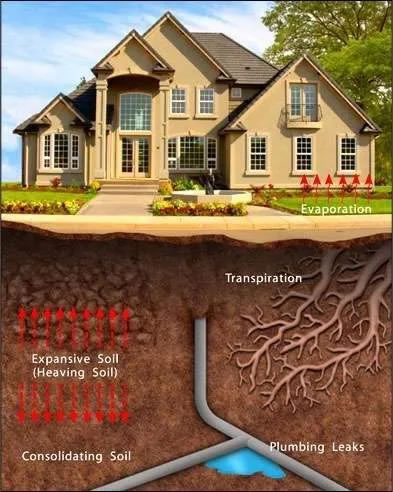

The possibility of the occurrence of foundation failure is something that everyone buying, selling or occupying a home should consider. Foundation problems are commonplace, largely because the soil conditions upon which residential and commercial buildings are constructed tend to be very unstable in our areas.

Our foundations are only as strong as the soil properties they are placed on. These soils are made up of thousands of years of sediments, mainly silts, clays and some granular soils.

How do you know if you have a foundation problem?

The following check list of symptoms should help you identify serious foundation movement:

-

Inspect for cracks in brickwork. Look for previous patching. Look for separation between door and windows and brickwork. Also check to see if chimneys or porches are moving away from the house or structure.

-

Look for cracks in interior wall of ceiling finishes and/or tearing of wallpaper, floor coverings, etc.;

-

Check to see if windows or doors bend, stick, or appear to be out of square.

- Re-occurring leaks in your ceilings, around chimneys, or increases in your water bills.

If you feel you may have a foundation problem or know someone that does, or if you are planning to build a home and would like to secure yourself against these types of failures, call a professional for a consultation, survey and estimate.